Some lean tools may be more appropriate for one business than another. however, kaizen, 5s, kanban, value stream mapping, and focus pdca are among the most useful lean tools. kaizen. kaizen is a lean tool that, when used correctly, fosters continuous improvement in quality, technology, processes, productivity, company culture, and safety.. It is time to use tools for lean from lean-tool.com "standardized work is one of the most powerful tool in lean / toyota production system. standardized work containing the current best practice, standardized work forms the baseline for kaizen or continuous improvement. as the standard is improved, the new standard becomes the baseline for. Lean methodology also has an expansive legacy outside the u.s., with companies such as toyota making considerable breakthroughs in the application of lean tools throughout the 1930s. in addition to being the first to correctly implement the lean tool just-in-time, for example, toyota is also known for creating its own lean production system ..

Seiton is the second step of the 5s method

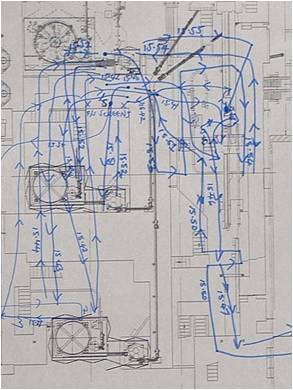

Process mapping your value stream

Creative ideas for backyard retreats, detached home

When talking about lean process improvement tools, many turn their eyes to six sigma, kanban and even to lean canvas.. but what these people forget is that the origin of lean is in the use of tools to improve processes in an agile and practical way, aiming to reduce waste and create a “lean” process..